Tutorial

Blender's Extra Objects

What is it?

While you could create an SVG file of a gear, Blender provides a very simple way to create gears and a few extra objects.What's the tutorial?

Extra Objects

- If you don't have Blender installed, download it from blender.org and install it.

- Open Blender

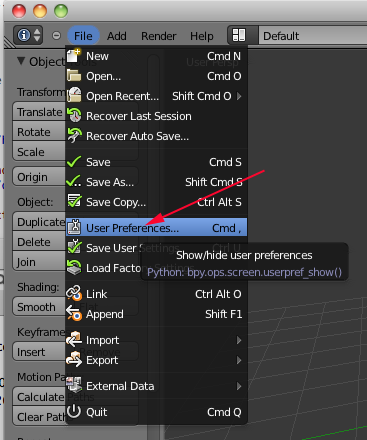

- If you have not enabled Extra Objects navigate to File>User Preferences or type (CMD+,).

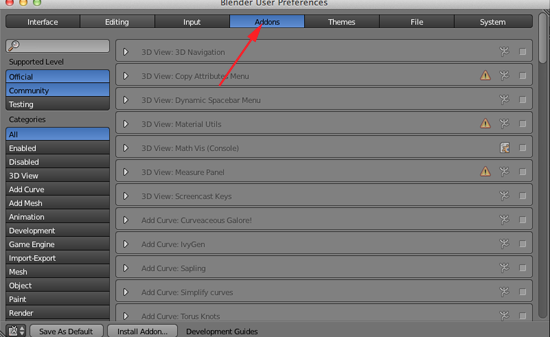

- Click on Addons

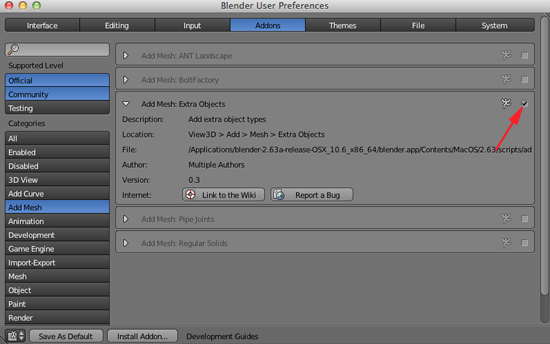

- Click on Add Mesh and toggle open Extra Objects and enable this Addon

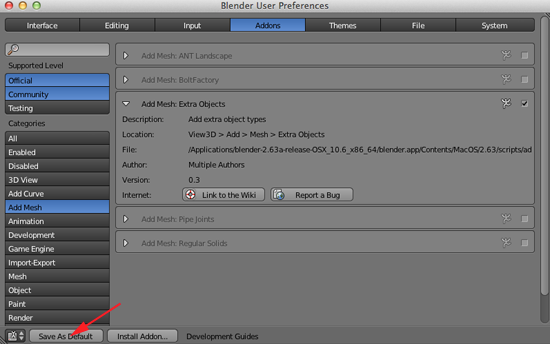

- Click on Save As Default

Gears

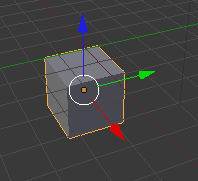

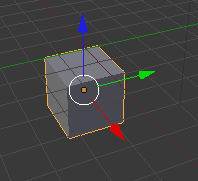

- If the cube is not selected (if there is not an orange line around it), RIGHT click on it to select it:

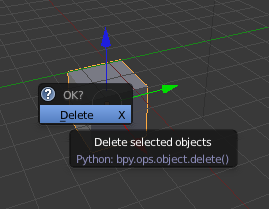

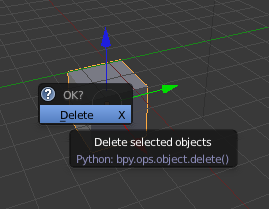

- Press X and click on Delete to delete the cube.

- Set your Viewport to Top Ortho (7,5)

- Place your 3D cursor in the center.

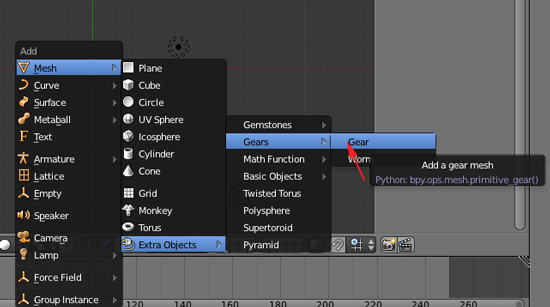

- Press SHIFT+A. Select Mesh>Extra Objects>Gears>Gear

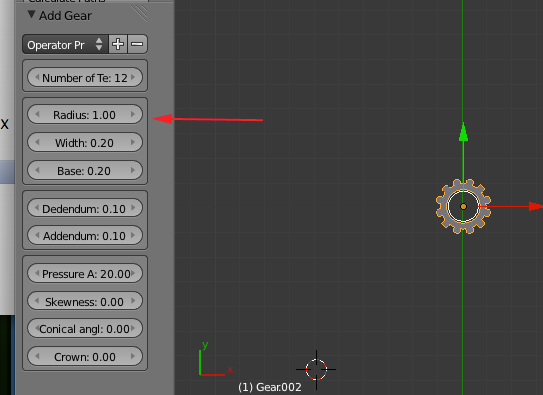

- Adjust the gear parameters in the tool shelf. You will have to make all the changes to the parameters before you make any transformations.

You use gears to slow down a motor and give it more strength.

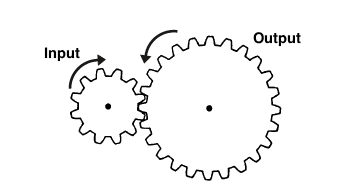

Torque refers to rotating strength. If the input gear is smaller, your larger gear will move slower, but the torque will be stronger.

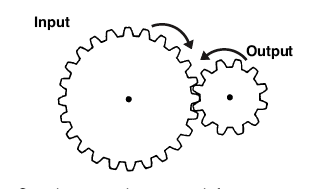

As the speed increases, the strength of the torque decreases (large input).

As speed decreases, strength increases (small input).

You also use gears when your mechanism that is controlled by a motor is separated from the motor by geometry. The gears allow you to transfer the rotation of the motor across this geometry. When designing, you will often work from mechanism back to motor.

You could use gears with the same number of teeth to move the rotation.

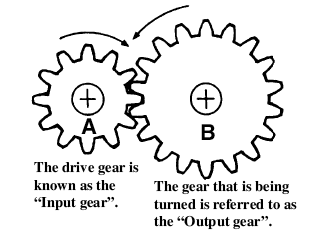

Gears are comparable to continuously applied levers; as one tooth is engaging, another is disengaging. The amount of teeth on each gear wheel affects the action on the gear wheel it engages or meshes with. The gear wheel being turned is called the input gear and the one it drives is called the output gear. Gears with unequal numbers of teeth alter the speed between the input and output. This is referred to as the gear ratio.

Gears also alter the direction of rotation. In the above example gear wheel A is rotating clockwise, but as it turns, gear wheel B is moved anti-clockwise.

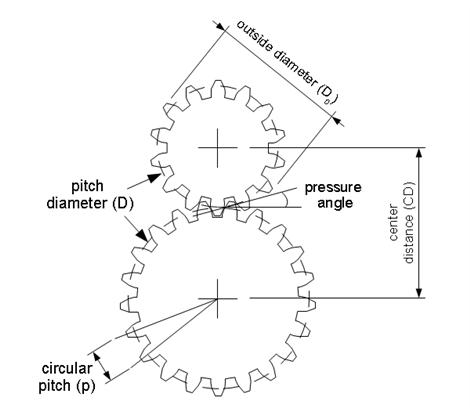

If you know any two things about a gear—outer diameter and number of teeth—you can use some simple equations to find everything else you need to know, including the correct center distance between them.- Number of Teeth (N)

- How many teeth are there in the gear

- Pitch Diameter (D):

- The circle on which two gears effectively mesh, about halfway through the tooth. The pitch diameters of two gears will be tangent when the centers are spaced correctly.

- Diametral Pitch (P):

- The number of teeth per inch of the circumference of the pitch diameter. Think of it as the density of teeth—the higher the number, the smaller and more closely spaced the teeth on a gear. Common diametral pitches for hobby-size projects are 24, 32, and 48. The diametral pitch of all meshing gears must be the same.

- Circular Pitch (p) = pi / P:

- The length of the arc between the center of one tooth and the center of a tooth next to it. This is just pi (ï€ = 3.14) divided by the diametral pitch (P). Although rarely used to identify off the shelf gears, you may need this parameter when modeling gears in 2D and 3D software like we're doing here. As with diametral pitch, the circular pitch of all meshing gears must be the same.

- Outside Diameter (Do):

- The biggest circle that touches the edges of the gear teeth. You can measure this using a caliper like Sparkfun.com's # TOL-00067.

Note: Gears with an even number of teeth are easiest to measure, since each tooth has another tooth directly across the gear. On a gear with an odd number of teeth, if you draw a line from the center of one tooth straight through the center across the gear, the line will fall between two teeth. So, just be careful using outside diameter in your calculations if you estimated it from a gear with an odd number of teeth. - Center Distance (C):

- Half the pitch diameter of the first gear plus half the pitch diameter of the second gear will equal the correct center distance. This spacing is critical for creating smooth running gears.

- Pressure Angle:

- The angle between the line of action (how the contact point between gear teeth travels as they rotate) and the line tangent to the pitch circle. Standard pressure angles are, for some reason, 14.5&Acir;° and 20°. A pressure angle of 20° is better for small gears, but it doesn't make much difference. It's not important to understand this parameter, just to know that the pressure angle of all meshing gears must be the same.

- Addendum:

- how much the tooth protudes beyond the pitch radius

- Dedendum:

- how deep goes the tooth before any fillet takes place

- Pressure angle:

- The angle between the radial direction and the tangent to the tooth at the pitch circle. 20 is a good value.

Some Rules

The value of the base circle is based on pressure angle.- The smaller the pressure angle, the smaller the base radius

- The addendum must be less than the dedendum

- The dedendum must be more than the difference between the pitch and the base radius.

All of these gear parameters relate to each other with simple equations.To Get You Have Equation Diametrical Pitch(P)

Number of teeth per unit lengthCircular Pitch(p)

Number of Teeth(N) & Pitch Diameter(D)

Number of Teeth(N) & Outside Diameter (Do)P=π/p

P=N/D

P=(N+2)/Do(approx)Circular Pitch(p)

Length of the arc from one tooth to the nextDiametrical Pitch (P) p=π/P Pitch Diameter(D) Number of Teeth(N) & Diametrical Pitch(P)

Outside Diameter (Do) &Diametrical Pitch(P)D=N/P

D=Do-2/PNumber of Teeth(N) Diametrical Pitch(P) & Pitch Diameter(D) N=P*D Center Distance(CD) Pitch Diameter(D)

Number of Teeth(N) & Diametrical Pitch(P)CD=(D1+D2)/2CD=(N1+N2)/2P

Stepping down has the advantage of producing more power although at a slower rate.

This

Stepping up produces a much faster output

speed, but mechanically delivers less power

This

Stepping up produces a much faster output

speed, but mechanically delivers less power

CALCULATING RATIOS

If the input gear (A) has 10 teeth and the output gear (B) 30 teeth, then the ratio is termed 3 to 1 and is written down as 3:1Ratio = No. of teeth on the output gear B (30)> No. of teeth on the input gear A (10) = 3/1 and is written down as 3:1

Simply divide the amount of teeth from the output by the input gear to work out the ratio. In the above example, for every complete revolution of the input gear the output turns 1/3 of the way round. In other words it takes three turns of A to rotate B once. This means you are slowing down the action and is referred to in engineering terms as Stepping Down. If B were the input gear and A the output gear, then the opposite happens and we Step Up. Then with one turn of the input gear the output gear would turn three revolutions, giving a ratio of 1:3.

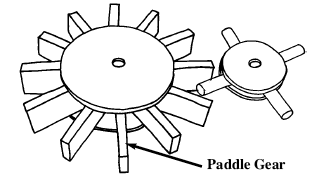

parallel gears work in a similar way to the In line ones but are much easier to construct. The larger one uses popsicle sticks instead of dowel and is referred to as a Paddle gear.

Designing

When designing and making gear wheels you need to apply a little common sense. For example, the load or pressure put on the gears in automata are usually very small compared to that of a car gear box. This allows you to get away with things that you couldn't in other machines. However, you still have to follow some simple engineering guidelines. You will need to identify what you want to get from the gears. Try running through this simple check list;- Do you want the gears to step up or

step down? (speed up or slow down

the performance).

- Do you want the gears to run

parallel, or at an angle of 90° to

change the direction of the drive?

- What size do you need to make

them? (small space means making

smaller gears and this can get tricky).

- You need to set your parameters before doing any transforms or using modifiers. Once you have your gears, scale them up in Blender

- RIGHT+click on the gear or gears and select File>Export>STL(.stl) Save the stl and open in MakerWare or ReplicatorG.

Gem Stones

- Create a new Bender document.

- If the cube is not selected (if there is not an orange line around it), RIGHT click on it to select it:

- Press X and click on Delete to delete the cube.

- Set your Viewport to Top Ortho (7,5)

- Place your 3D cursor in the center.

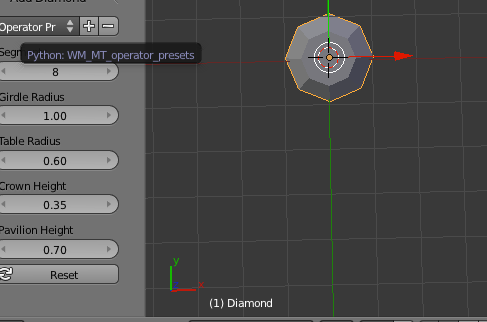

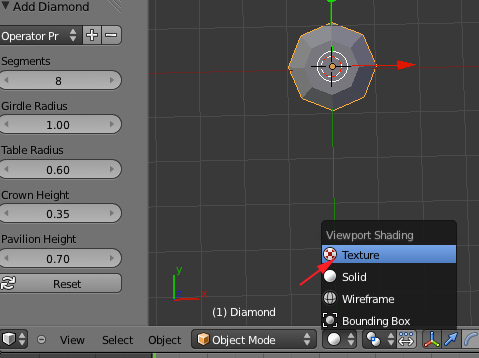

- Press SHIFT+A. Select Mesh>Extra Objects>Gemstones>Diamond.

- You will have to adjust the parameters before making any transformations. Adjust the gemstone parameters in the tool shelf

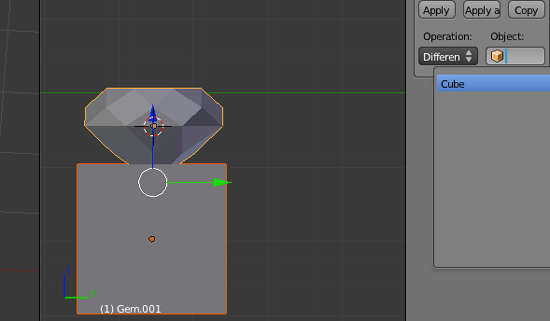

- If you want to attach the gemstone to a ring, you might want to take a cube and boolean difference the pointed part of the gemstone.

- If you add a a gem and modify the parameters, you might create problems with your mesh. To see the issues, switch from Solid to Texture viewport shading:

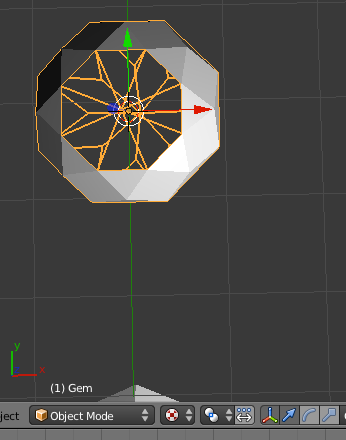

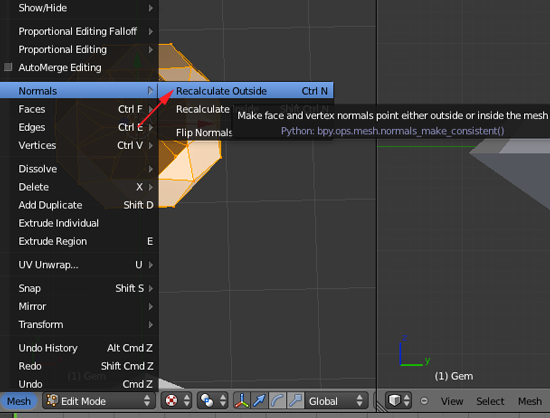

- If you see a problem like this:

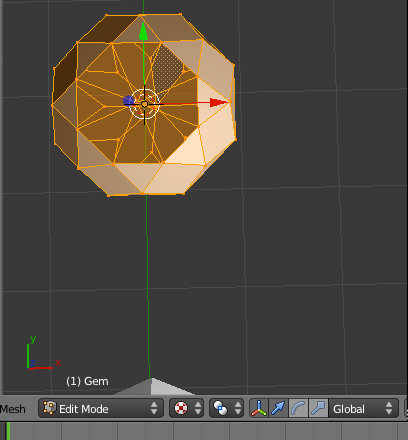

Toggle into Edit Mode

- Press CTRL+N or navigate to the Mesh>Normals>Recalculate Outside

- RIGHT+click on the gem and select File>Export>STL(.stl) Save the stl and open in MakerWare.

Now what?

- Upload your tessellation to Thingiverse

- Come back tomorrow for more information and inspiration!